By Jutta Berns-Mumbi

We have – without a doubt and, indeed, at last – arrived at a situation where protecting the bottom line and protecting the climate means the same thing. To keep to an overall target of below 1.5°C global temperature increase, CO2 emissions must decline by 45% before 2030 and renewable energy will need to supply 70 – 80% of power by 2050. So how do we get there?

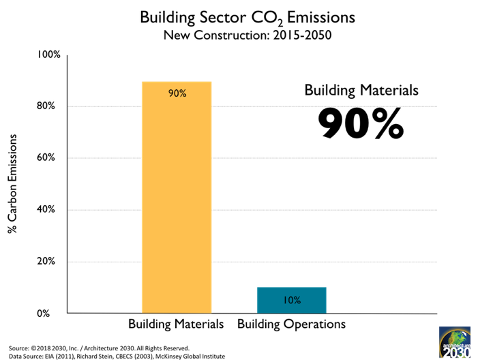

One of the pathways sits squarely within our built environment, where we can unlock – or rather drawdown – carbon budgets at an accelerated speed. Buildings are currently responsible for 39% of global carbon emissions, of which 11% are locked up in building materials (embodied carbon) with the remainder (28%) coming from building operations.

As we continue to decarbonise operations over the next few years, embodied carbon will continue to grow in importance as a proportion of total emissions. Pursuing the goal of decarbonising the world’s building stock by 2050 in order to meet global climate goals quite simply means that the new metric is ‘speed’ and rapidly increasing efforts to tackle embodied carbon at a global scale as well.

So what does this mean in practice for the built environment? How and where do we find the optimal solutions to decarbonise the “stuff that surrounds us”? And, indeed, who holds the main levers?

For starters, we have to review the currency with which we value both our environment and our climate. Put carbon on the balance sheet. Value the invaluable. The World Green Building Council’s call to action to investors to scale up investments in support of net-zero embodied carbon, which in turn will trigger market demand, speaks volumes.

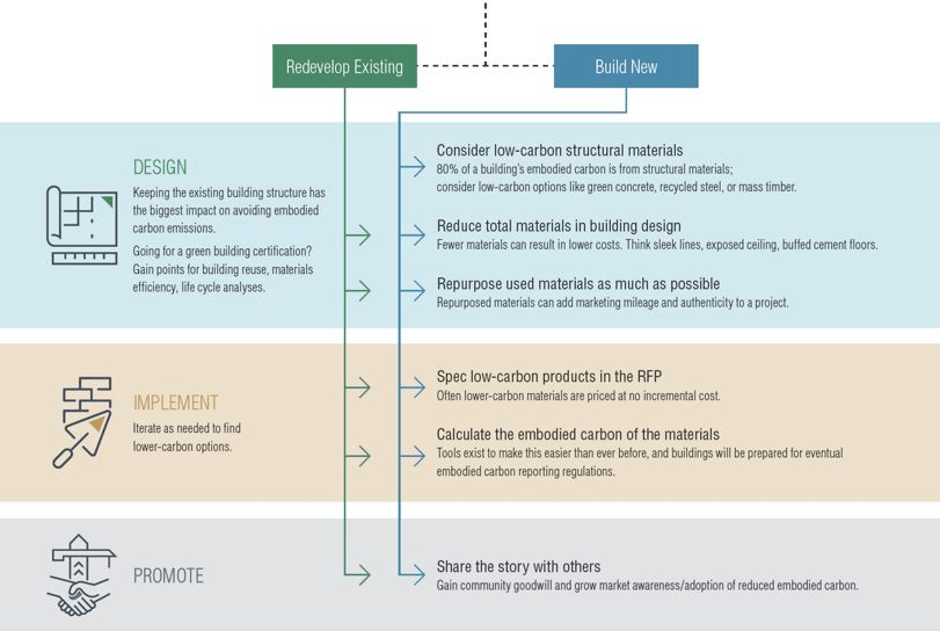

And of course, we cannot get to a net-zero future by stealth, but by getting full buy-in across the value chain within the built environment is key to moving fast, coupled with a clear understanding and drive of accelerated decarbonisation. Collaboration is key. So, as we work across the value chain in decarbonising our built environment, it is the cost consultants, the quantity surveyors, who may just become the rock stars of embodied carbon removal: supporting designers in choosing low-carbon structural materials, specifying low-carbon products in RFPs and ultimately including embodied carbon calculations in cost analysis, planning and control. Tools that ease this process are increasingly and widely available. Circular Ecology has compiled an up to date list of publicly available tools, which can be accessed here.

As we no longer have a choice whether or not we want to design for a zero-carbon future, once we start thinking about the net-zero challenge as just another industrial revolution, everything kind of falls into place.

Jutta Berns-Mumbi is the Founder and Managing Director of ecocentric. Linkedin